Introduction to Aluminum CNC Machining Services

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computerized controls to operate machine tools. It allows for the precise and automated production of parts and components, granting a level of accuracy that manual machining cannot achieve. Among the array of materials used in CNC machining, aluminum stands out as a preferred choice due to its unique properties. Aluminum is lightweight yet possesses remarkable strength—a combination that makes it an ideal solution for industries such as aerospace, automotive, and electronics.

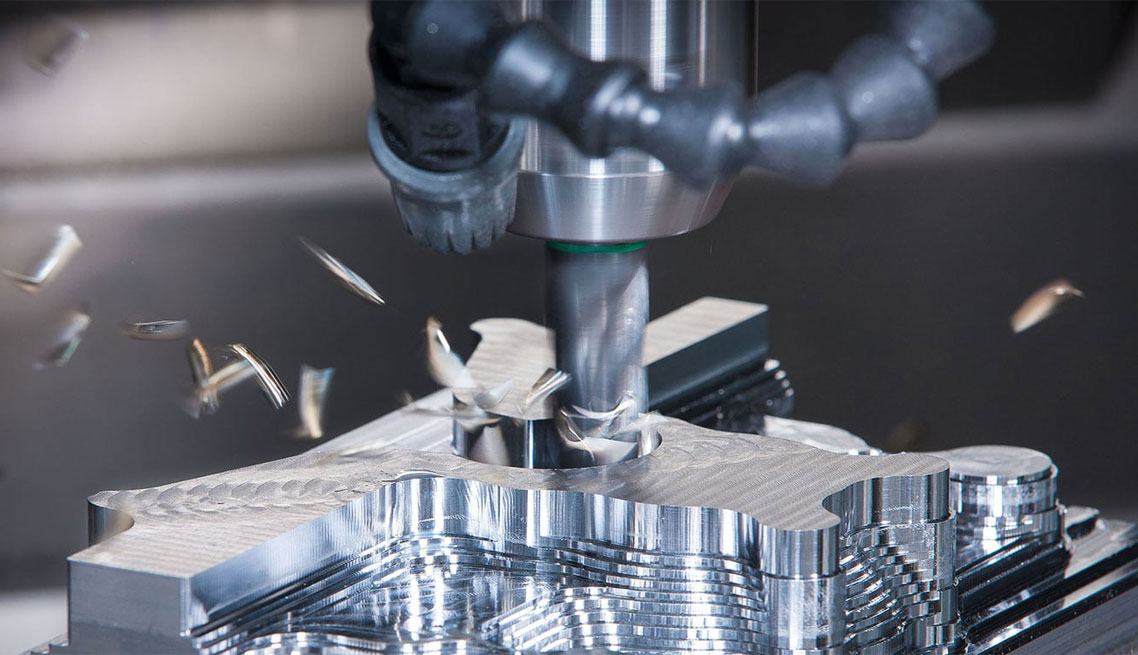

The malleability of aluminum further enhances its appeal in the CNC machining landscape. This malleability facilitates various machining processes, enabling intricate designs and complex geometries to be achieved with ease. CNC machining processes such as milling, turning, and drilling are particularly effective when used with aluminum, allowing for high precision and the production of finely detailed components. As a result, manufacturers are able to meet stringent tolerances and quality standards set by their respective industries.

Diverse types of CNC machining processes can be employed when working with aluminum. For instance, CNC milling involves the removal of material through rotary cutters, while CNC turning uses a lathe to produce cylindrical shapes. Each method ensures that the end product aligns with technical specifications and design parameters, further emphasizing the role of precision in manufacturing. The importance of such accuracy cannot be overstated; it directly correlates with the functionality and reliability of the final product, which is crucial across various applications.

In summary, aluminum CNC machining represents a sophisticated approach to manufacturing that leverages the advantages of aluminum’s material properties. Its lightweight, strong, and malleable nature, combined with the precision offered by CNC processes, positions aluminum as a leading material across multiple industries. This foundational understanding sets the stage for exploring the specific benefits, processes, and applications of aluminum CNC machining in subsequent sections.

Our Expertise: 3-Axis and 5-Axis CNC Machining

In the realm of aluminum CNC machining services, the choice between 3-axis and 5-axis machining represents a significant factor in the production process, particularly when dealing with complex designs and tight tolerances. Both methods have distinct capabilities that cater to various industries and applications, making it essential for clients to understand their differences and advantages.

3-axis CNC machining involves the movement of the cutting tool along three linear axes: X, Y, and Z. This technique is often used for simpler parts or those with less intricate geometries. The advantages of 3-axis machining include straightforward programming and reduced setup time, making it a more cost-effective solution for projects requiring less dimensional complexity. It is particularly effective for producing flat components, slots, and contours in aluminum, showcasing its reliability for straightforward machining tasks.

On the other hand, 5-axis CNC machining introduces two additional rotational axes, allowing the tool to approach the workpiece from virtually any direction. This capability is crucial for manufacturing complex aluminum parts where precision and detail are paramount. The advantages of 5-axis machining include enhanced accuracy and the ability to achieve intricate designs in fewer setups, ultimately leading to reduced lead times. This versatility is indispensable for industries such as aerospace and medical device manufacturing, where tight tolerances and complex geometries are often required.

Our expertise in both 3-axis and 5-axis CNC machining services allows us to meet a diverse range of client needs efficiently. By leveraging the strengths of each machining method, we can select the most suitable process for specific project requirements. This ensures optimal outcomes for all our clients, whether they need straightforward parts or highly detailed components.

Comprehensive CNC Services Offered

Aluminum CNC machining encompasses a variety of services that cater to the diverse needs of different industrial applications. Among these, three core services stand out: CNC milling, CNC lathe, and CNC turning. Each of these processes has distinct characteristics that contribute to the production of high-quality aluminum components.

Custom CNC Milling Near me is a subtractive manufacturing process that utilizes rotary cutters to remove material from a workpiece. This process is particularly effective for producing complex shapes and detailed features, making it ideal for intricate aluminum parts. CNC milling machines can execute various operations, including contouring, drilling, and slotting, thus providing versatility in design without compromising precision. The capability to work with multiple axes ensures that even the most complex geometries can be achieved with ease.

CNC lathe machining, on the other hand, is primarily used for producing cylindrical parts. This method rotates the aluminum workpiece against a cutting tool, allowing for the creation of parts with precise diameters and smooth finishes. CNC lathes are especially useful for producing high-volume items where consistency and accuracy are paramount. This process significantly reduces the possibility of errors and wastage, enhancing the overall efficiency of production.

CNC turning complements the machining services available and is used for creating round parts with specific dimensions, often utilized in automotive and aerospace applications. The precision offered by CNC turning is crucial for meeting tight tolerances in products that require high reliability.

Beyond these machining processes, the anodizing surface treatment service is noteworthy for its vital role in enhancing aluminum products. Anodizing increases corrosion resistance and durability while also allowing for aesthetic customization through a range of color options. This treatment not only improves the longevity of the aluminum components but also bolsters their visual appeal, making them suitable for a variety of applications where both performance and aesthetics are valued.

Why Choose Us for Your Aluminum Machining Needs

When it comes to selecting a provider for aluminum CNC machining services, our company stands out as a reliable choice. We have made significant investments in state-of-the-art facilities, equipped with the latest technology in CNC machining, which allows us to deliver exceptional precision and quality. Our machinery is specifically designed to handle various aluminum alloys, ensuring that we can produce tailored components that meet the specific requirements of our clients.

Our comprehensive industry knowledge is another critical reason to partner with us. With years of experience in Aluminum Precision Machining, our skilled team understands the nuances of working with this versatile material. From design consultation to the final product, we provide expert guidance throughout the process. We prioritize customer engagement, making sure we comprehend your specific machining needs and applying our expertise to maximize efficiency and effectiveness.

Moreover, our commitment to quality assurance sets us apart in the CNC machining landscape. We adhere to stringent quality control measures, ensuring that every project meets the highest standards. Our dedication is demonstrated by our portfolio of successful case studies, where we have helped diverse industries achieve their goals through finely crafted aluminum components. Clients have consistently praised our attention to detail and timely project delivery, which not only reinforces our credibility but also builds trust among potential customers.

In addition to our technical capabilities, we emphasize excellent customer service. We foster open lines of communication, allowing clients to feel supported and involved at every project stage. By prioritizing customer satisfaction and cultivating lasting partnerships, we are not just a service provider; we are allies in your success. Therefore, when looking for unparalleled aluminum CNC machining services, consider partnering with us for a seamless experience tailored to your needs.

✅ Want real-time updates and expert tips? Connect with us on Facebook