Aluminum Precision

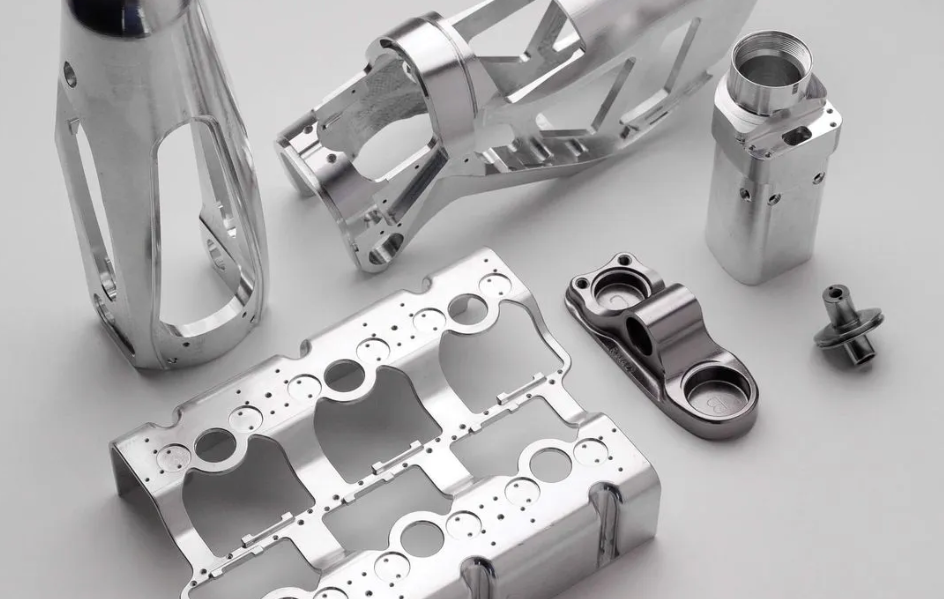

Aerospace and automotive industries need accurate parts and those of good structural integrity. Aluminum precision machining offers both, delivering strong, lightweight components with unmatched accuracy. The higher CNC machines deal with complex geometries and maintain close tolerances that these industries need.

Working with AMS Vietnam, top CNC precision machined suppliers, guarantees consistent results and optimal surface finishes. These components are subjected to severe environments and hold important uses such as the engine systems and structural parts.

Why Aluminum Is Ideal for Precision Machining

The strength and lightweight nature of aluminum can be considered the most preferred material in many industries. It is machinable such that it enables quicker production at a lower cost of tool consumption. This reduces the expenses and maintains a level of performance even with the part designs that have some complexity.

Machinists Value Its Thermal Properties

Aluminum is also heat-resistant, so it does not produce as much thermal deformation when being cut. This maintains accuracy to one part and finish. It is an important feature that is advantageous to high-speed operations.

The corrosion resistance of aluminum is an added advantage in high performance environment. CNC operators are able to make parts that are dense without defects, suited to be integrated in the aerospace or car industries.

Role of CNC Machining in Aerospace Component Fabrication

Weight, durability, and dimensional accuracy must be precise for aircraft components. The use of CNC machinery can help in manufacturing state-of-the-art aluminum parts that satisfy these requirements. Such machines are super precise with a scale of microns.

Suppliers Understand Aerospace Tolerances

Trusted CNC precision machined suppliers maintain ISO and AS certifications. They have tests, inspections, and quality checks at each stage of production.

These processes make the components of aerospace, such as brackets, housings, and panels, safe when exposed to stress. We also have aviation regulations on traceability and documentation, in which the aerospace suppliers give priority, ensuring that every part is manufactured using the Best Precision Machine for top-quality results.

Benefits of CNC Machining for Automotive Applications

Efficiency and quality rule the way in the car business. Aluminum Precision Machining parts that are CNC-machined help to cut down the weight of the vehicle, which helps fuel consumption and handling. Other parts, such as the engine mounts, transmission cases, and suspension brackets, must be accurate to the nearest fraction.

Machining Reduces Assembly Challenges

Stringent tolerances give low levels of fitting mistakes and cut down on assembly. CNC machining saves time since it does not require secondary adjustments.

Moreover, the strength-to-weight ratio of aluminum also enables lighter parts to be constructed without safety being traded away. CNC shops turn parts that can work dependably under different circumstances of the engine and warming of the engine.

How CNC Precision Machined Suppliers Ensure Quality

Skilled suppliers are well-experienced with high-quality machines and engineers in order to create complex specifications. They enforce stringent procedures of inspection and trace each production process. Their systems monitor dimension information, finish, and structural integrity.

Collaboration Enhances Output

Suppliers work much closely with clients when they can produce a better result. They know the objectives of design and give suggestions on materials and processes.

This cooperation guarantees an improved prototype, fewer manufacturing mistakes, and less time to turn around. Quality suppliers also provide growth and use of quick scaling and post-machining processing, such as anodizing.

Conclusion

Aluminum precision machining plays a critical role in producing lightweight, accurate, and durable parts. The industry of aerospace and automobile manufacturers uses this approach to achieve the targets of performance, safety, and compliance with regulations. CNC machining leaves no two parts behind as it adheres to the requirements of the tightest industry standards.

By partnering with certified CNC precision machined suppliers, companies gain access to advanced machines, expert teams, and scalable production solutions. AMS Viet is interrelationships that assist manufacturers to remain competitive in highly demanding and rapidly changing industries.

Like and follow us on our Facebook page

FAQs

- What makes aluminum the best material for precision machining?

Aluminum is lightweight, machineable, and rust-resistant. It does not loosen easily. It is then perfect for aerospace and automotive applications.

- How do CNC machines enhance accuracy in Aluminum Precision Machining parts?

CNC machines utilize exact digital routes when cutting. AMS Viet reduces the element of human error and provides reliable, repeatable outcomes. This will guarantee precision at all times.

- What makes CNC precision machined suppliers reliable?

They employ modern equipment, qualified procedures, and rigorous checks. They also provide agricultural design and versatile production services. These activities enhance the quality of parts and speed.

- Which aluminum parts are typical of the field of aerospace?

The standard components are the brackets, housings, and structural panels. These are some of the parts that help in weight saving and being durable. The suppliers are also aviation compliant.

- Are CNC parts made of aluminum used by automotive companies?

Indeed, aluminum components make the vehicle more efficient and lightweight. CNC machining is strong, fits, and reliable. It also facilitates complex designs on automobiles.