CNC Machining Service

With the changing environment of manufacturing in industry, precision, speed, and flexibility are no neither optional features. As industries push for better quality and faster production, CNC machining services have become a key driver of success. Across the aerospace and electronics industries, the modern company is largely dependent on the wave of automated machining to ensure the competitiveness and reliability of its products.

AMS Viet provides a turnkey solution to the CNC product constituting into enabling manufacturers to achieve growing needs without compromising quality. They have a well-developed machine center with capabilities of producing precision parts through automation of processes, process certifications, and flexibility of materials. Paying close attention to aluminum precision machining, they ensure that all the projects conform to international performance and accuracy standards.

Precision and Repeatability in Modern Manufacturing

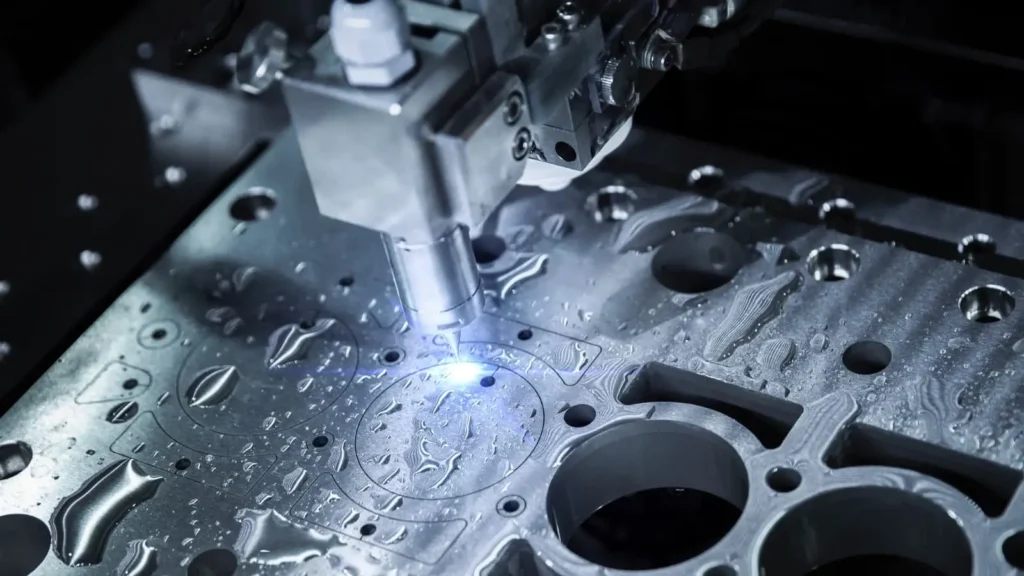

Modern production is based on accuracy. The difference between manufacturing aircraft parts or medical equipment, the slightest variation will become a significant problem. CNC machining services offer repeatable, error-free results with exceptional control over shape, size, and structure. CNC does not have to rely on manual operations in the production of parts down to its dimensions, as in contrast to manual operations, CNC uses pre-programmed paths in the production of the parts.

CNC Turning and Milling with Tight Tolerance Control

Their CNC turning and milling is tailored to projects that do not have time to pass up. Turning is ideal on cylindrical products, whilst more complicated shapes are milled. They are both digitally controlled to move in smooth and precise movements across any material.

All the machine set-ups are adjusted before being operated, making use of close tolerances and clean finishes. Experience: Being skilled in the processes of aluminum precision machining, they provide the parts that may match the most essential structural and aesthetic requirements. Their highly sophisticated measuring equipment test every part that has been cut so that the outcome is perfect in every production run.

Flexible and Scalable for Every Industry Need

One of the biggest benefits of CNC machining services is their ability to adapt. A client may only require a single prototype or thousands of completed parts, and CNC technology can grow as large as it is necessary. It is also a process that is consistent, cost-effective, and fast-even in cases where there are variations in the specifications of the project during the production process. This type of flexibility is built into AMS Viet.

Rapid Tooling for Speed and Accuracy

Speed is necessary in order to remain competitive. The rapid tooling process enables faster production of a client of a concept. After a design has been accepted, it is coded directly on the CNC machine. It is where the parts are designed, developed, and perfected within the shortest time possible.

This aids companies in avoiding the time-consuming methods of traditional mold-making. Clients are capable of testing their sections before confidentiality, minimizing rework, and effortlessly switching into mass manufacturing. It also enhances communication between design and manufacturing, and hence, all the details are identified before scaling up. When it comes to tooling services offered by AMS Viet, efficiency and precision go hand in hand.

Surface Finishing and Post-Machining Excellence

The process of quality does not cease with the machine’s stop. Any part needs to complete some finishing processes, such as cleaning, coating, and assembly, to be up to industrial standards. Failure to do this exposes parts to corrosion, poor fit, or poor performance. That’s why complete CNC machining services must include post-machining and finishing solutions. They have over 40 finishing services, including anodizing, polishing, and protective silicone.

Specialization in Aluminum Finishing and Protection

Being a team of specialists in the area of aluminum precision machining, they specialize in durable surface treatments. Although the aluminum parts are lightweight and strong, they require quality finishes to enhance their resistance against wear and corrosion. The anodizing services offered by them enhance the surface of objects to make them firm and develop a professional look.

They do the inspection of each part in several stages with the help of their quality control teams. This creates consistency of finishes as well as dimensions, even on coating. Delivering precision provided by CNC and promoting professional finishing, they can facilitate their clients in producing durable, reliable, and beautiful components to serve all kinds of applications.

.jpg)

Conclusion

The modern manufacturing world does not need only high-speed production. It needs accuracy, flexibility, and extensive service. CNC machining services meet these demands by combining smart technology with exact results. The CNC systems have proved essential in industrial production as they can cut, shape, and finish parts with micron accuracy.

They provide an entire solution and not only design and tooling but also post-machining and finishing. Since they specialize in aluminum precision machining, they have a strong role to play in high-performance industries. To companies that want to increase production and avoid quality losses, AMS Viet offers capabilities that are up to date with contemporary manufacturing standards.

🔍 Want to see our quality in action? Check out real-time updates on our Instagram page

FAQs

- What industries benefit from CNC machining services at AMS Viet?

They are applied to such industries as aerospace, electronics, and the medical industry. Their CNC machining services deliver precise, durable components. Quality control is very critical to each project.

- How do they realize the accuracy of the parts?

They have high-quality CNC machines and tolerance control. Inspection of all parts is done through the use of laser devices and CMM. This maintains uniformity in the accuracy of the production line.

- What materials do they specialize in?

They deal in both metals and engineering plastics. They specialize in aluminum precision machining that is required for high performance. Processes on all materials are carried out to satisfy specifications.

- What is the size of the orders that they can take?

They are prototyping and mass production supportive. Their dynamic CNC manufacturing process is responsive to fluctuations in volume demands. At any level, clients will always get consistent results.

- Will they do post-machining?

They have services pertaining to finishing, anodizing, and full assembly. All of them are in-house to guarantee expedience and coherence. All of the sections are offered ready to use and complete.