Turning Services

Turning operations play an important role in modern manufacturing as they are used to perform high-precision shaping of round or cylindrical elements. With the demand for reliable, quick, and scalable production, CNC turning services offer unmatched advantages over manual methods. The services enable manufacturers to manufacture fast and consistent parts in small quantities.

AMS Viet focuses on delivering high-quality and new-generation CNC turning solutions to both prototypes and high-volume manufacturing. As certified CNC precision machined suppliers, they use state-of-the-art turning centers to deliver precise parts for industries like medical, aerospace, and electronics. Their end-to-end process ensures that every bit is produced to perfect dimensions at a low lead time.

What Makes CNC Turning Services So Precise and Efficient?

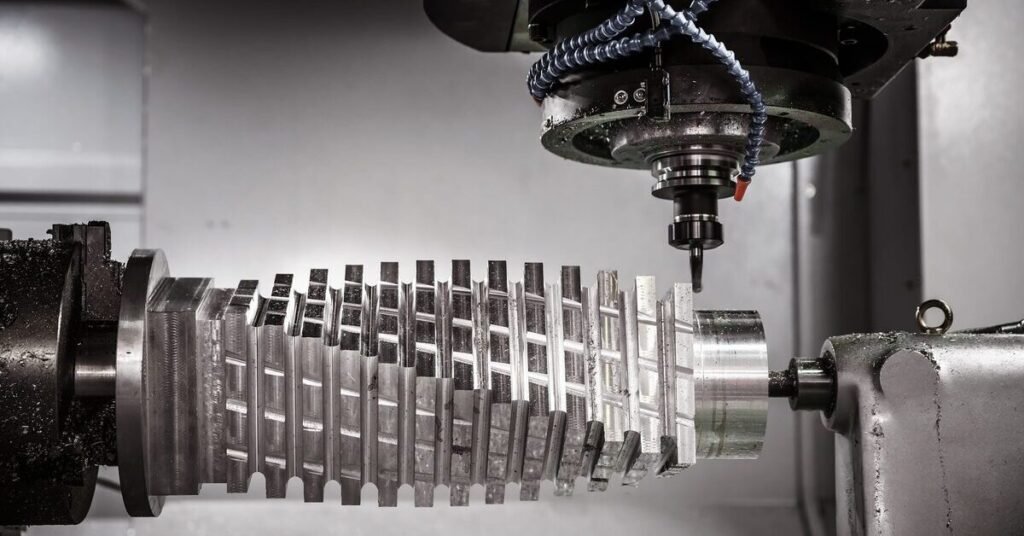

CNC turning is done by spinning a workpiece, and the material is scarred by a tool that can cut to achieve a shape. It is perfect in symmetrical elements, like shafts, spacers, and rings. This is done on a digital basis following instructions on an automated CNC system that does the job perfectly and extremely repeatably. To perform on the micro-level, they have automatic lathes and Swiss turning machines.

Advanced Turning Capabilities with Consistent Output

AMS Viet’s CNC turning services offer both single-axis and multi-axis operations. This enables them to make basic to very intricate versions of geometrical figures. At every job site, CAD data is used to develop exact cutting instructions to execute that job.

High-grade tooling and real-time monitoring are used so that the avoidance of errors during cutting occurs. That leaves sections having finishes that are smooth and tight tolerances, and which may need slight to no finishing. Due to the system of AMS Vietnam, customers will receive reliable results on each order, no matter the complexity of a part or how large the batch they order.

Applications Across Multiple Industries

CNC turning is not specialised in any particular use; this is because it aids in most industries. From producing automotive shafts to electronic enclosures, CNC turning services adapt to varied project demands. The high accuracy, fast, and scalability of turning systems make them key in consumer and industrial manufacturing.

Specialization in CNC Aluminum and Complex Parts

A great emphasis has been placed on aluminum CNC turning, with components that are lightweight, durable, and corrosion-resistant. Such components find common application in the automotive, electronics, and machinery industries. It is also their facility that allows them to machine complex, multiple-operation parts having internal grooves, threads, or tapers.

This shortens factory turnaround time and moves projects along as the same processes (design, machining, and quality assurance) all occur under a single roof. They can fulfill both prototype and mass order, which makes them a reliable supplier to any company that requires continuity of behavior in turned parts.

Quality Control and Finishing for Final-Ready Parts

Tight machinery should be supported with thorough inspection to guarantee high standards of parts. Quality checks are a core part of reliable CNC turning services, helping manufacturers avoid flaws and meet regulatory requirements. In tight-fit assemblies, surface finish and dimension accuracy are particular requirements. It is a firm that observes strict quality procedures that include laser measurements and CMM inspections.

Turnkey Delivery from Raw Material to Finished Component

The benefit of using this company as they are that they are capable of handling all the aspects of the production process. They take care of them all, including sourcing the material to the packaging. This is time-saving, cost-saving, and does not allow the exclusion of any component.

AMS V makes the supply chain easy for the clients by providing CNC turning, as well as finishing and assembly services. They have their systems streamlined in terms of quality and efficiency. This end-to-end model is the reason why numerous companies decide to collaborate with AMS Viet in the long term, as a CNC manufacturer.

Conclusion

CNC turning services play a vital role in modern manufacturing, offering precision, speed, and repeatability. CNC turning, whether 1 piece or a thousand pieces, allows the components to be made to exact requirements without delays and defects. It is a reliable remedy for industries that cannot tolerate inconsistencies.

They stand out as one of the most reliable CNC precision machined suppliers, combining cutting-edge technology with strong quality assurance. They are practitioners of the turning services, and their aluminum and multi-component part turning ensures a comprehensive end-to-end support of the production. When you team up with the AMS Viet, you invest in precision and productivity.

Stay updated with our latest CNC machining innovations — follow us on Facebook!

FAQs

- What can they work with the CNC technology?

They deal with aluminum, specialty alloys, and steel. Their turning centers have been designed to be precise on different materials. Any part is handled to precise specifications.

- Are their CNC turning services suitable for prototypes?

Yes, they can meet prototype orders as well as large-volume orders. They also provide flexibility to their systems in terms of the changes of design. Consistency in quality is what is offered to the clients.

- What do they do about ensuring the accuracy of turned parts?

They apply CMMs and real-time inspection. Dimensional precision is confirmed by laser measurement. This ensures that there are defect-free parts all the time.

- Do they offer finishing services for CNC turning?

Yes, they have anodizing, polishing, and surface coating. These give it durability and other aesthetics. Finishing is entirely in-house.

- Why choose AMS Viet for CNC turning services?

As trusted CNC precision machined suppliers, they provide complete production support. They guarantee quick, accurate, and high-quality performance in every step.