Micro turning is a specialized machining process focused on producing small, highly precise parts for various industries such as medical, aerospace, and electronics. As the demand for compact, intricate components grows in modern manufacturing, micro turning has become increasingly vital for its efficiency and accuracy. This article delves into the micro turning process and its applications.

Production of micro turning parts

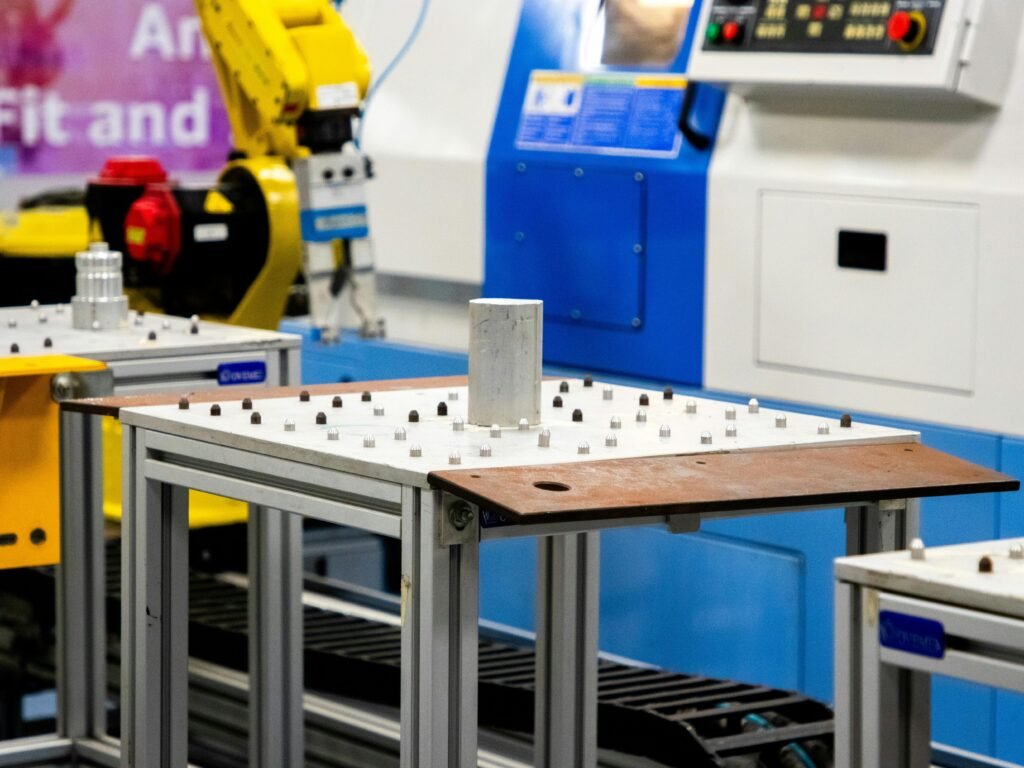

Micro turning involves using a lathe to remove material from a workpiece to achieve the desired shape or feature. While similar to traditional turning, it operates on a much smaller scale. Micro turning machines utilize specialized cutting tools designed for working with small components, often crafted from durable materials like high-speed steel or tungsten carbide to withstand the forces and temperatures involved in the process.

One of the standout benefits of micro turning is its exceptional precision. The process can achieve tolerances of just a few microns, making it ideal for producing intricate shapes and features requiring extreme accuracy. Furthermore, micro turning is highly efficient, allowing for the rapid production of large quantities of parts.

Application of micro turning parts

The applications of micro turning are vast and varied. In the medical field, it is used to manufacture tiny components for medical devices such as implants and surgical tools, where even the slightest deviation can have serious consequences. In the aerospace industry, micro turning produces small parts for aircraft and spacecraft, such as sensors and actuators, which must endure extreme conditions while maintaining the highest levels of precision.

In the electronics industry, micro turning plays a crucial role in the production of components like microchips and sensors. These parts demand exceptional precision to ensure proper performance and functionality.

Conclusion

Micro turning is an essential process in modern manufacturing, offering unparalleled precision and efficiency for producing small, complex parts. Its applications span multiple industries, including medical, aerospace, and electronics, where accuracy and quality are paramount. This makes micro turning an increasingly attractive choice for manufacturers seeking reliable solutions for high-quality, intricate components.

At TDB, we provide micro turning service and others. Find out more our services.