Reliable CNC Precision

Selecting the best CNC precision machined supplier does not simply imply anyone who can cut metal. It is based on developing a reliable relationship that will help you achieve long-term production objectives. Whether it is quality tolerances to clean finishes or timely deliveries, a good supplier can improve the whole manufacturing process.

Such a fact is worth considering since companies such as AMS Vietnam can compete well due to the combination of advanced equipment, experienced engineers, and close quality control. If you often search for “custom CNC milling near me,” partnering with such a professional team ensures consistent, precision-built parts that meet every requirement.

Understand the Supplier’s Machining Capabilities

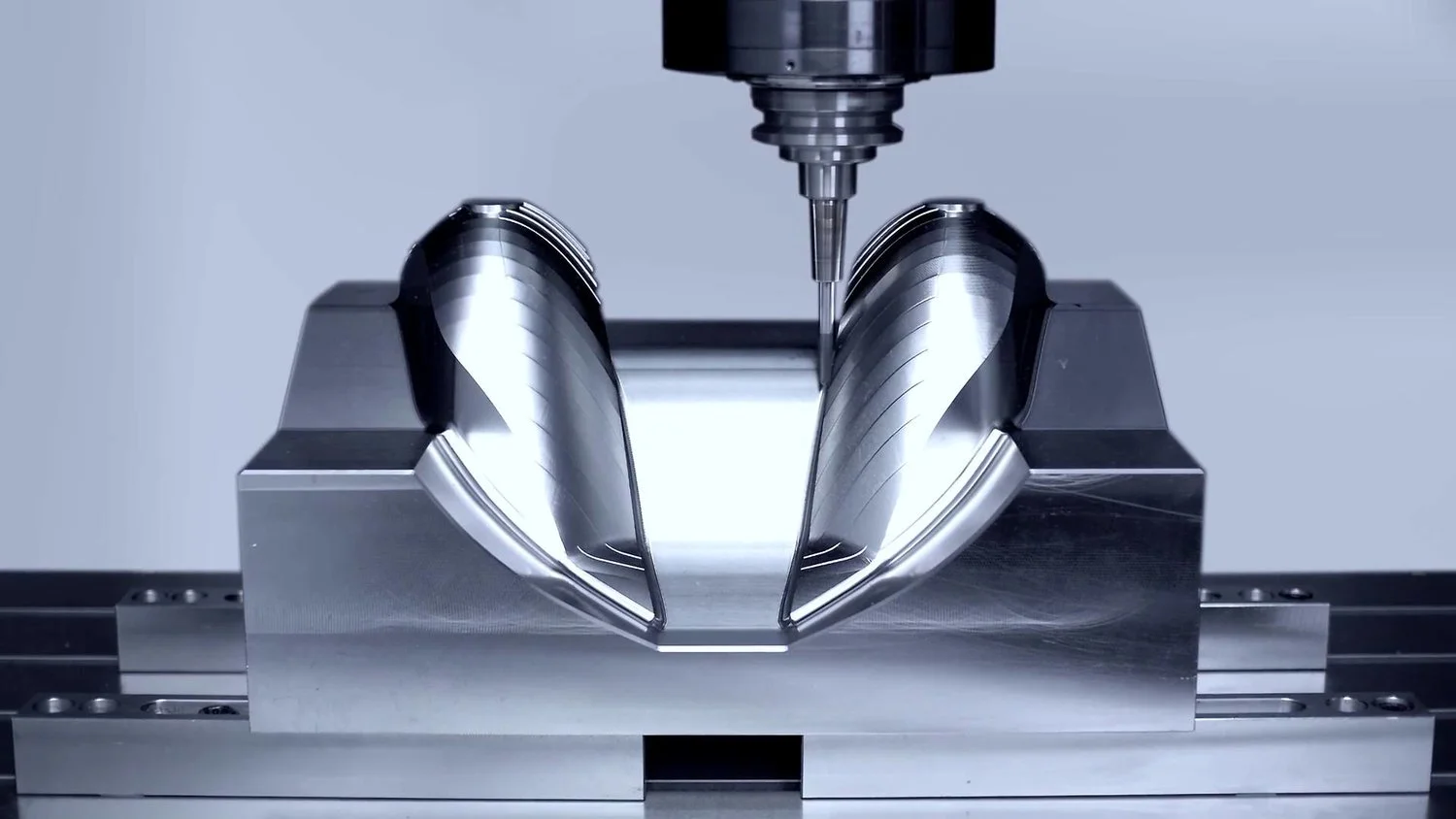

A competent supplier of CNC should possess flexible and superbly performing machinery. This encompasses 3 axes, 4 axes, as well as even 5-axis machines to serve varying designs and tolerances. They have invested in multi-axis CNC machineries to create prototyping as well as bulk production in the aerospace, automotive, electronics, and electronics industries. The machines also minimize human errors since they require fewer setups and repositioning.

Advanced Machines Handle Complex Geometries

As well as possessing new machines, they do not take a break there, but seek to give full value to that opportunity through process expertise. The team they have is conversant with working with intricate part shapes and unusual design needs. You may require internal grooves, deep pockets, and/or asymmetrical surfaces; they possess the tools and expertise to do it there and then.

They will avoid delays and cleaning by writing programs with efficient programs and fixtures ready to machine on more sides than one. This enhances turnaround times and prevents the integrity of parts. There are no inconsistencies to worry about it as every piece can be received as planned and can be used immediately.

Check for Industry Certifications and Quality Standards

They have in place stringent standards in order to have all their CNC machined parts pass inspection, tolerance, and performance. When something is certified, it is traceable, there is accountability, and also consistency in the line of each job. Strict-protocols suppliers minimize the variability and make sure that even the large-quantity orders keep the quality of the first part to the last one.

Inspection Systems Guarantee Accuracy

This is because at AMS Vietnam, all the parts pass through various stages of quality checks. This encompasses first article inspection (FAI), in-process inspection, and final inspection by the use of Coordinate Measuring Machines (CMM). They have internal records that follow the calibration of tools and the performance of the operators in order to be fully transparent.

The difference between them and other companies is that they pay so much attention to being accurate than is required. They incorporate digital gauges and vision systems, and real-time statistical analysis to find and fix problems with a part even before it arrives at your facility. Such a degree of detail puts clients at an advantage, especially when performance and reliability are sacrosanct.

Evaluate Supplier Experience in Custom CNC Milling

The fourth one is experience in the field of custom CNC milling. Firms with a long history in the area are familiar with how to adapt to other materials as well as the size and applications of parts. They refer to many years of experience working in the industry for every client. They collaborate with the engineers, designers, and procurement teams to check the optimum processes for certain parts. Such practical experience can enable them to anticipate the problems in the production process and prevent them beforehand.

Skilled Engineers Improve Outcomes

Their engineering team is not reading a blueprint; they are optimizing it. They arrive at design-for-manufacturing (DFM) suggestions that decrease complexity with the retention of functional usefulness. This working relationship assists clients in cutting down the cost of production and lead time.

This is directed at clients, not just by giving them parts but also wisdom, assistance, and regular feedback during the production process. This avoids wasteful trial and error and enables project scaling up, between prototyping and mass production. Engineers of AMS Vietnam become part of your extended group of experts.

Conclusion

Choosing reliable CNC precision machined suppliers means focusing on capability, experience, quality assurance, and delivery performance. Getting all the ticks, they ship out the best quality of parts in numerous industries. Their staff assists you in both the quality and promotion results of your manufacturing through the usage of expert opinion, modern technology, and speedy delivery.

If you’re searching for custom CNC milling near me, they offer local responsiveness with global standards. With a supplier like AMS Vietnam, your parts will not only be on time, they will specifically fit your needs- all the time.

For more details and information, follow us on our Instagram page

FAQs

- What constitutes a reliable CNC precision machined supplier?

They mix up the latest machines, qualified engineers, and verified quality systems. These aspects make it accurate in each detail. A stable supplier fulfills your requirements and supplies on time.

- What do they do to help with custom CNC milling projects?

They give support in optimized design, material choice,e and effective machining sequence. Their team also works in analyzing every component to make it quality and affordable. These are also technical advisors all through.

- What are the reasons for certification in CNC machining?

The certifications demonstrate that the supplier meets the international quality standards. They guarantee traceability, inspection, and control of the process. The customers get components that address safety as well as performance standards.

- What are the Turnaround times of AMS Viet?

At AMS Viet, clients can get the normal and express services based on the urgency of the project. They have effective systems that guarantee on-time production. They equally respond to the capacity requirement through customers.

- Is it available to me in consultations on my project?

Yes, both local and international consultations are welcome in AMS Viet. They have a unit that offers technical assistance and project design. This allows efficient communication and proper results.