ISO Certified CNC Precision Machining Services

Custom CNC Parts, Aluminum & Stainless Steel Components, High-Precision Manufacturing

AMS Viet delivers top-quality precision CNC machining for aluminum, stainless steel, and other materials. Our engineering expertise ensures high-precision components for OEM and industrial applications worldwide.

Instant Quote Request

Send Online Services

Our Services

CNC Machining Precision Shop

Precision machining is a manufacturing process that uses computer-controlled machine tools to create parts with very tight tolerances and high levels of accuracy. AMS Viet operates one of the leading precision machining shops in Vietnam, offering comprehensive solutions for industries such as aerospace, medical, and defense.

We work with a wide range of materials, including aluminum, steel, stainless steel, plastics, and more. As a CNC precision machining company, we focus on producing parts with exacting dimensions and complex geometries.

10+

Years In Business

150+

Happy Clients

2.0k

Square Metter

30+

Experience Staff

Our Experted In

AMS Provide Precision CNC Machining Services

CNC Milling Service

AMS specializes in precise mechanical processing tailored to customer requirements. All products undergo strict quality control in compliance with international standards ISO 9001:2015

CNC Turning Service

With a team of highly experienced engineers, AMS is confident in delivering products with optimized technology while reducing costs and ensuring the highest value for our partners.

Quality Assurance

We are dedicated to helping customers optimize their products. Our team is available 24/7 to provide full support for all technical and technological requirements.

Additional Services

We Also Offer

We do offer precision machining of metal parts including custom surface treatments by means of anodic oxidation, color surface finish or sandblasting. All according to the customer specifications with the highest quality and flexible delivery times.

Why Choose Us

Six Reasons For People Choosing Us

Guaranteed Quality

Based by GB/T, EN AW, ASTM, AMS-QQ-200, JIS, and customized.

Turnkey Solution

OEM&ODM, Assembling, Package and Transport Solution.

Advanced Manufacturing

State-Of-Art Facilities and Cutting Edge CNC Manufacturing.

Time Availability

We support 24/7 and quote all time on days.

Quick Response

Our Sales support team feedback within 24h

1 Year Warranty

We will change one by one if have any issued

Ready to Start Your Project?

Partner with AMS Viet for precision CNC machining and engineering solutions. Upload your designs or request a quote today and bring your ideas to life.

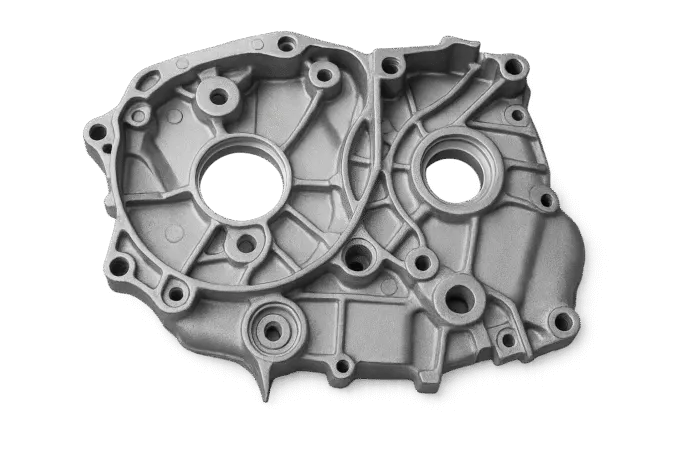

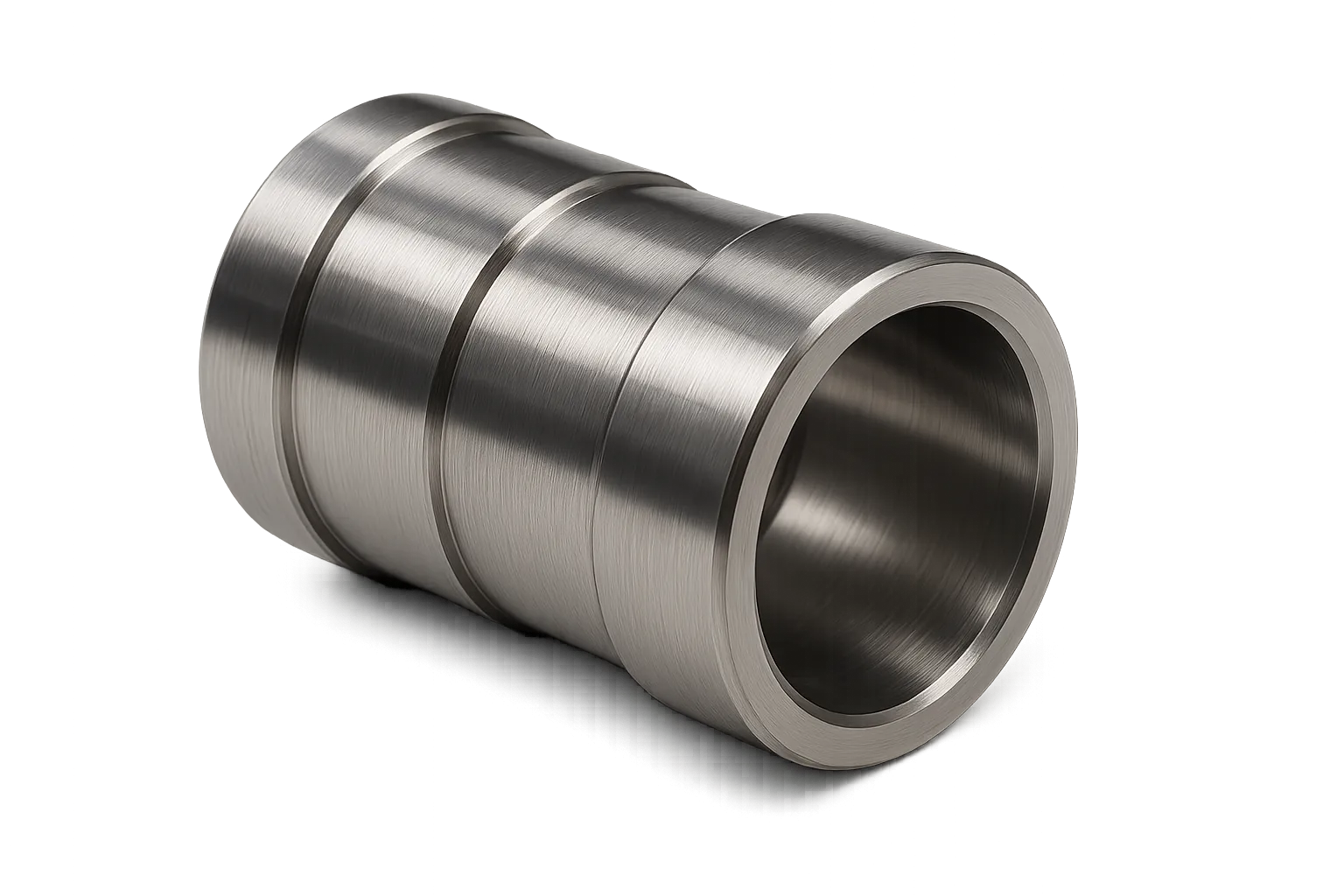

CNC Machining Parts We Made

We are a leading CNC machining manufacturer of precision machinery components, aluminum profiles, and OEM products, serving customers worldwide, including the United States, Canada, Australia, and Europe. Our products are of high quality and accuracy.

Aluminum Tap & Drilling

I am a repeat customer of this business, and they never disappoint.

Automatic Bar Feeder Turned

I am a repeat customer of this business, and they never disappoint.

Precision CNC Turning

I am a repeat customer of this business, and they never disappoint.

CNC Machining Parts

I am a repeat customer of this business, and they never disappoint.

Aluminum Extrude Part

I am a repeat customer of this business, and they never disappoint.

CNC Mill & Turning Part

I am a repeat customer of this business, and they never disappoint.

Don't Know What To Start With?

Get A Solutions For Precision CNC Machining Parts Mfg

Offices

CNC Manufacturing

We supply high-precision machined parts at high quality and with CNC Machining services. We had 10 years experience to exported precision machine parts to the world as USA, EU, Australia, Canada,…

Free Consultation

Get A Free Quote

Learn More From

Frequently Asked Questions

Lead times vary by complexity and quantity:

- Prototypes: 3-7 business days

- Small batches (10-100 pcs): 2-3 weeks

- Production runs (100-1,000 pcs): 3-4 weeks

- High volume (1,000+ pcs): 4-6 weeks

Rush services available for urgent projects. Contact us for specific timeline requirements.

- 3-Axis: Cuts in X, Y, Z directions. Best for flat/prismatic parts, most economical

- 4-Axis: Adds rotation (A-axis), enabling machining on multiple sides without repositioning. Better for cylindrical parts with features

- 5-Axis: Adds two rotational axes, can reach any angle. Ideal for complex geometries, compound curves,and single-setup manufacturing

We select the appropriate machining method based on part geometry, tolerance requirements, and cost optimization.

Yes, we can machine customer-supplied materials. We require:

- Material certification/test reports

- Sufficient quantity (include extra for setup/testing)

- Clear identification and traceability

- Advance notice for proper handling

Note: We cannot guarantee material quality or properties for customer-supplied stock.

Yes, we provide complete material documentation:

- Mill test reports (MTR)

- Chemical composition analysis

- Mechanical properties

- Heat lot traceability

- Certificate of Conformance (CoC)

Material certifications are included at no additional charge.

Absolutely! We provide complimentary Design for Manufacturability (DFM) analysis with every quote. Our engineers will:

- Identify potential manufacturing challenges

- Suggest design modifications to reduce costs

- Recommend optimal materials and processes

- Optimize tolerances for functionality

- Provide alternative approaches

This collaborative approach often saves 20-40% in manufacturing costs.