Surface Finishing for CNC Machined Parts

Surface finishing is part of manufacturing, especially for CNC machined parts. It uses techniques specifically designed to modify the surface characteristics of a component to meet targeted functional, aesthetic, or performance-related needs. Surface finishing beautifies the part and increases its performance characteristics, such as corrosion resistance, wear resistance, and surface roughness.

What is Surface Finishing?

Surface finishing is the process by which one changes the surface of a machined part concerning texture, appearance, and functionality. Depending on the part needed, the finish could be mechanical, chemical, or electrochemical.

CNC machining leads to high accuracy and repeatability of a workpiece. However, the components may have features on their surface which impact both form and finish.

One common issue is tool marks—fine lines or grooves left by the cutting tool—which may affect both aesthetics and functionality. Techniques like polishing or secondary finishing can help address these marks. It may not be aesthetically desirable or functionally suitable.

Machined features such as burrs, raised edges, particles, or small ridges forming at the boundary of the features necessitate deburring operations.

Minor marks that may take the form of scratches on the surface due to the machining process, handling, or transport are undesirable from an aesthetic point of view. They may be a source of further mechanical difficulties later on.

Common Surface Finishing Techniques for CNC Machined

Surface finishing plays a vital role in determining the quality and performance of CNC machined parts. Here, we discuss some standard finishing processes in various industries.

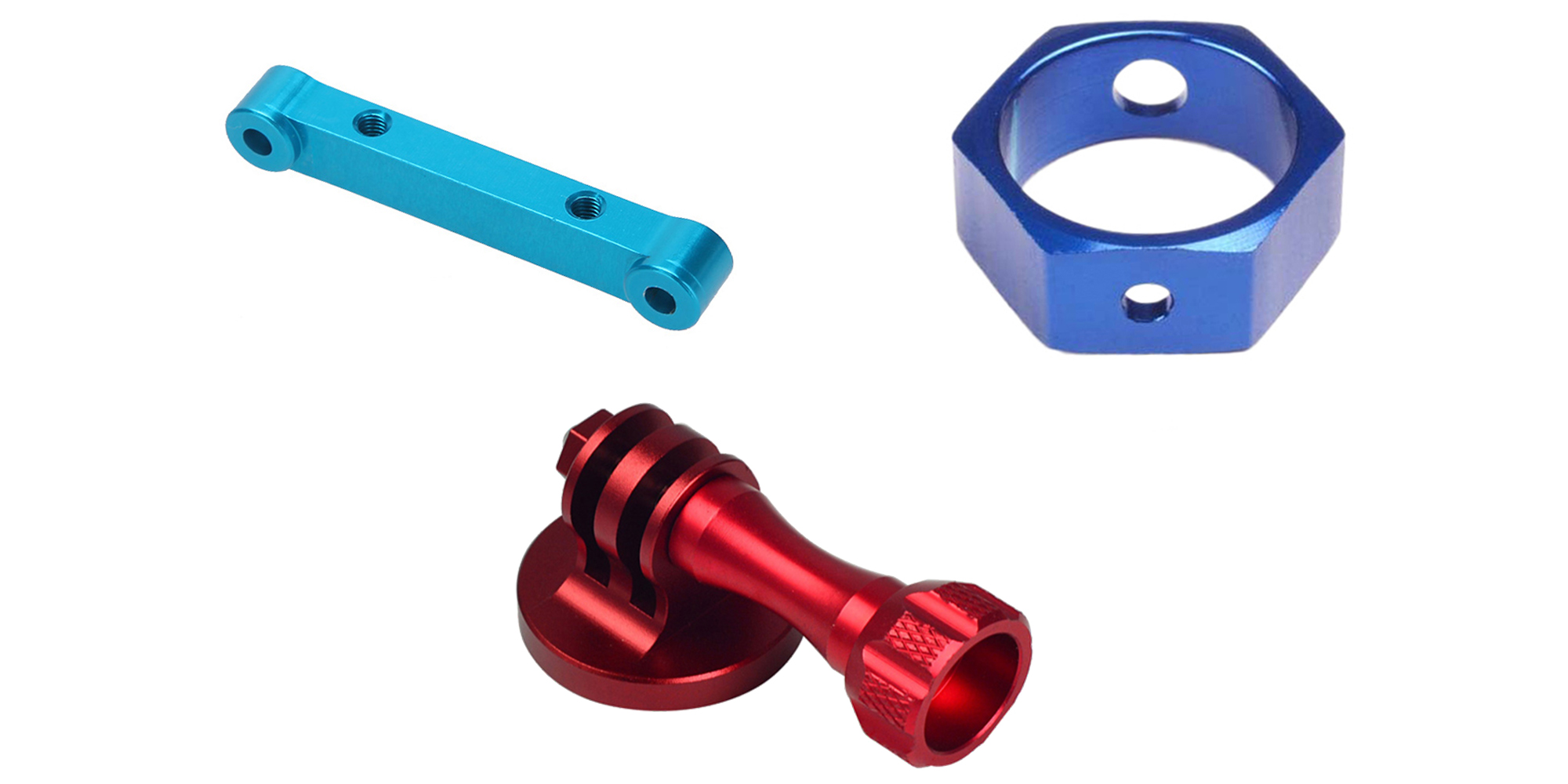

ANODIZING

Anodizing effectively improves the corrosion protection, mechanical properties, and appearance of products, especially aluminum. This procedure involves forming a robust and rust-proof oxide film on the surface of the metal. Anodizing forms an oxide layer, forming a coating around the metal. Not only does this improve the metal’s characteristics, but it also contributes to the aesthetic value of the final product.

Process

- Surface Preparation: Part cleaning occurs before applying the anodizing process. Thorough cleaning removes oils and dirt. Operators may use mechanical or chemical pretreatment techniques like polishing or etching.

- Immersion in Electrolyte Solution: After cleaning, technicians put the part in an electrolyte bath, often acidic, sulfuric, or chromic acid. This bath creates an electrolytic process, resulting in the formation of the oxide layer. In this process, the part itself forms the anode of the system. A cathode is aluminum or leads just opposite the anode.

- Application of Electric Current: Technicians pass direct current (DC) through the part and the cathode, and an electrochemical process occurs at the part. Ions from the electrolyte react with the aluminum atoms on the part’s surface and produce aluminum oxide (Al₂O₃). This oxide layer is porous at first and facilitates the subsequent fabric treatment, such as dyeing.

- Coloring and Sealing: The anodized layer allows dyes to penetrate, making it easy to dye the part. Organic or inorganic dyes penetrate the pores. Sealing is the last process to increase corrosion protection and prevent the color from fading. This involves raising the part to a boiling point, whereby the aluminum oxide hydrates and closes all pores. Other sealing types include chemicals such as nickel acetate to protect the surface further.

Types of Anodizing

- Type I (Chromic Acid Anodizing): It uses Chromic acid as the electrolyte and forms a thin and smooth anodic layer. However, it has a lower abrasion resistance than the other coatings. It is most applicable in aerospace parts where the fundamental properties are fatigue strength and high corrosion resistance.

- Type II (Sulfuric Acid Anodizing): This method is familiar with a sulfuric acid solution as an electrolyte. The parts in this process are thicker than those in chromic acid anodizing. Type II anodizing is favorable for dyeing the surface and is suitable for aesthetic use. It is famous for most small appliances, car accessories, and buildings where appearance, moderate resistance to rusting, and strength are desirable.

- Type III (Hard Anodizing using Sulfuric Acid at Lower Temperatures): Comparable to Type II but at cooler temperatures and higher voltages. It produces a considerably denser and more rigid oxide coat. It is famous for its high abrasion resistance coupled with high hardness properties. The anodic layer is thicker, up to 100 microns thick, and has improved rate properties regarding wearing and corrosion. Appropriate for demanding roles such as aerospace goods, military products, and industrial equipment. These applications require maximum durability of the surface or the whole device. Possible applications include pistons, gears, and other moving parts.

BEAD BLASTING

Bead blasting is another method of surface finishing that impinges high-pressure oxide-base glass beads on the surface of a material. Adjusting the process allows for smooth and rough surfaces with the help of the abrasive media. It is common in beautification, surface preparation, or stripping off surface contaminants such as rust or paint.

Process

- Surface Preparation: Involve washing to remove the residual oils or other easily detachable contaminants.

- Blasting Cabinet or Machine Setup: Technicians position the part in a bead blasting cabinet or machine fixture. The cabinet is a closed space where blasting occurs, and the abrasive media does not fly away from it.

- Pressurized Air and Abrasive Media: Operators use compressed air to eject the abrasive material, mostly glass beads, against the part’s surface. The degree of surface treatment depends on the pressure of the air and the kind of media used in the process.

- IVControlled Surface Finishing: The operator can determine the amount of pressure, the closeness of the surface to which it is applied, and the angle of the media’s application. This is necessary for complete control of the finish. Bead blasting is suitable for working on different parts in different ways, depending on the need.

- Post-Blasting Cleaning: The operators wash the part after blasting to remove any blasting media or dust left on it. This helps avoid interference resulting from contamination by other elements before the part has to undergo operations such as coating or assembly.

Types of Bead Blasting

- Glass Bead Blasting: This blasting employs spherical glass beads as abrasive media. The resulting surface finish is comparatively smooth and uniform. This blasting method is more suitable for manufacturing a matte or satin surface on the part. The glass beads are less abrasive than other blasting known media. It only removes a little material, making it applicable for polishing or surface cleaning and washing the surface. It is frequently helpful in household appliances, cars’ interiors and externals, furniture, light industry products, and other parts. In these applications, a smooth and beautiful look is essential.

- Aluminum Oxide Blasting: Employ a more complex and more extensive aluminum oxide. These materials are more rigid and smaller than the premier grit. Due to their hardness, aluminum oxide significantly removes more material from the surface than glass beads. It is useful where a slightly rougher surface or more excellent material removal is necessary.

- Plastic Bead Blasting: It employs plastic beads as the abrasive media, thus minimizing the rigorous treatment of the parts. Thanks to the thin plastic shells, they only cut into the metal a little. The process offers a fine surface finish without adversely affecting the strength of the particular part. Plastic bead blasting is a suitable option for cleaning softer metals or delicate parts, often used in automotive and aerospace manufacturing.

- Silicon Carbide Blasting: One of the most aggressive techniques involves using silicon carbide particles. Silicon carbide is among the hardest materials used in the abrasive media family. It works well before rigid material and aggressive removal. It results in a more irregular surface and is applicable for a situation where one wants a stronghold or clamping on the part. Some applications include cleaning turbine blades, castings, high-intensity parts, and many others that require a robust surface before further treatment.

ELECTROPOLISHING

Electropolishing is an accurate electrochemical process that dissolves slightly material off the surface of metal parts. This technique is the opposite of electroplating and is more akin to dissolving, polishing, and smoothing. Electropolishing has main applications in iron-chromium, aluminum, titanium, and nickel alloys. Therefore, it is helpful for sectors that need high cleanliness and surface purity levels, like the food industry, medical equipment, and pharmaceuticals.

Process

- Surface Preparation: Before electropolishing, metal part cleaning occurs for degreasing. Cleaning eliminates any substance that may hinder the electrochemical process.

- Submersion in Electrolytic Bath: Operators immerse the metal part in an electrolyte bath. The bath comprises an acid solution, more often a sulfuric acid and phosphoric acid solution. In the electrochemical part of the system, the ‘part’ acts as the anode, while the cathode is an inert material such as stainless steel or lead.

- Application of Electrical Current: Operators apply an electrical current between the part anode and the cathode. The current causes the oxidation layer from the part to dissolve in an aqueous solution. Material removal rapidly increases for the curved peaks local to the cathode surface rather than for the curved valleys. This selective removal contributes to flattening the surface, allowing the part to be polished to give a smooth surface.

- Material Dissolution: The electropolishing process strips off a thin, precise layer of material (usually in the range of.001 to 02 mm). They accumulate on the electrolyte until the right surface finish is reached. The final surface finish appears superior and refined to other mechanical polishing processes.

- Surface Smoothing and Polishing: Electropolishing leaves the surface smooth, shiny, and ‘bright’ compared to its original state. In addition to its aesthetic aspect, it dramatically minimizes roughness at the microscopic level and helps reduce the chances of corrosion.

- Post-Polishing Cleaning and Inspection: After the electropolishing treatment, the surface finishing part is washed in water to eliminate the electrolyte solution. Checking the surface finishing part guarantees that the suitable material is removed.

Comparison of Surface Finishing Methods

The best surface finish for the CNC machined parts depends on features such as the type of material used, the application requirement, and the part’s working conditions. The most crucial decision is selecting the surface finishes as they regulate the performance, endurance, and, finally, the price of the part. All the materials under discussion react differently towards specific finishing procedures, and procedures such as anodizing are usually standard on aluminum. Likewise, it is necessary to consider the function of the part under discussion. For example, using actual wear resistance, the components should be anodized tough.

On the other hand, electropolishing could benefit parts in incredibly sterile environments. Environmental exposure is also an essential factor, especially for those parts in corrosive environments, high or low temperatures, or chemicals. Aesthetics also affect the choice, mainly where industries such as customer electronics and automotive sectors, among others, use techniques such as polishing and anodizing. Budget considerations are essential in surface finish selection, as more protective and visually appealing options often come at a higher cost. In this case, it is highly requisite to consider the performance requirements against the costs to make the right decision.

| Finishing Method | Cost | Durability | Aesthetic Appeal | Common Materials | Typical Applications |

| Bead Blasting | Low | Moderate | Moderate (matte finish) | Aluminum, stainless steel | Automotive parts, aerospace components, electronics |

| Anodizing | Moderate | High (corrosion and wear-resistant) | High (colored options) | Aluminum, titanium | Aerospace, automotive, consumer electronics |

| Electropolishing | High | High | Moderate (smooth surface) | Stainless steel, aluminum | Pharmaceutical equipment, food processing, medical devices |

Conclusion

Surface finishing is an essential component of overall manufacturing when dealing with CNC machined parts, bearing a tight influence over functionality and appearance factors.

Anodizing, bead blasting, and electropolishing processes improve properties such as corrosion resistance, wearability, and surface finish, giving the components an aesthetic look.

Each finishing method addresses requirements or concerns related to the part’s material and intended use. Choosing the correct surface finishing technique relates to the efficiency and durability of the CNC machined parts.

Other attributes, including exogenous conditions, influence this decision-making process because of product performance demands. Costs of production are another essential factor.

Understanding the specifics of a particular surface finishing method is vital to making the right choices for their individual needs based on functionality, cost, and aesthetics for their specific products.

Follow our official Instagram page for more information