CNC Machine

CNC machining has revolutionized contemporary production, particularly where precision is of the essence. Companies that do business based on the precision of engineering require machines that are capable of producing accurate results, consistency in results, and high speeds. Selecting the best CNC machine involves understanding a range of features—everything from axis motion to material compatibility must be assessed carefully. Their objectives are always the same: quality production that will be error-free and error-free.

AMS Vietnam is a full-cycle CNC machining company that addresses the needs of different industries. They are precise and of good quality in all their prototyping, through to the finished product. They have the strength in the high CNC equipment, as well as the experience in various industries.

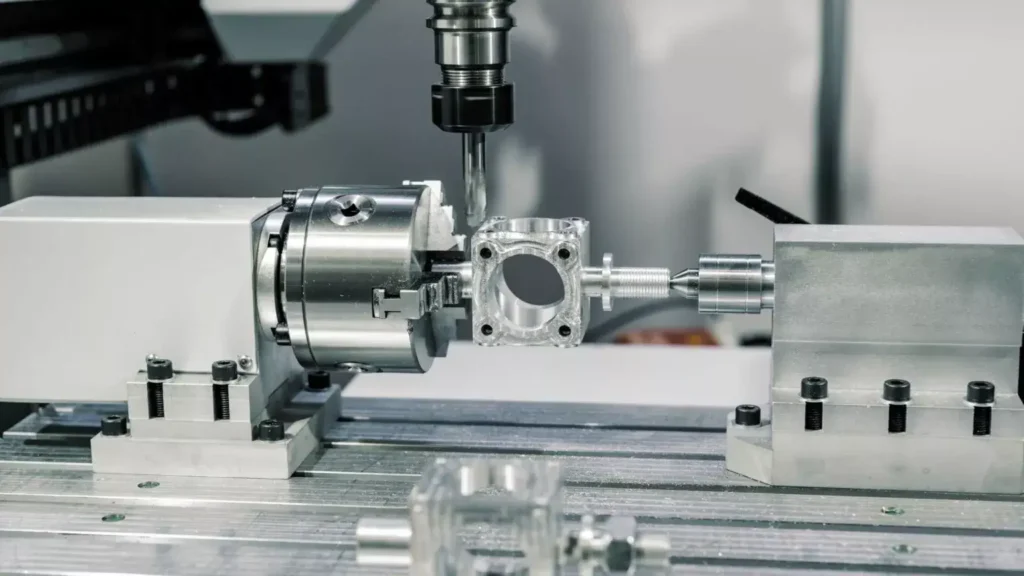

High Precision Starts with Advanced CNC Capabilities

High-precision manufacturing is all about being able to succeed at the scale of your equipment. The best CNC machine needs to offer tight tolerance control and smart automation. The characteristics, such as the number of axes, the speed of the spindle, and the materials compatibility, are very important in determining its accuracy. Devoid of such essentials, your production is likely to be distorted with misalignments and with inefficient repeatability. CNC principle also requires quality control and calibration of the precision machines. These are the performance features of AMS Vietnam machining.

Consistency and Control in CNC Turning Services

The stability and control represent the importance of the CNC turning that they provide. Their shop has high technological turning centers that favor both prototyping as well as large orders. CNC turning machines act by perfecting the detailed shapes by spinning the material and cutting off the material that one does not want to have. It is ideal for cylindrical parts that need precise measurements.

Using certified systems and automatic configurations, they eradicate manual operational mistakes and boost the pace of the process. This brings precise parts each time. They also use Swiss-type and automatic lathes, which increase the precision that they have. The services satisfy the needs of challenging industries where none of them should deviate.

Tooling and Machining Accuracy Make All the Difference

Tooling and machines are also important to the accuracy of every component. The best CNC machine integrates quality tooling systems that support various materials and complex geometries. It is not a matter of cutting–it is a matter of how clean, how speedy, and how controlled that cut is. Reliable CNC precision machined suppliers prioritize tooling compatibility as much as machine design. They have rationalized their tooling strategy via customized fixtures, multi-axis capabilities, and improved cutting plans.

Rapid Tooling with Full Cycle Manufacturing Support

The rapid tooling services they offer do not consist of a simple machine setup. These services comprise part design check, prototyping, as well as end mass production. They give the customers the ability to observe the design flaws and correct them by creating tooling when the product is still in its developing stages. That discourages delays and expensive corrections after production.

Their methodology promotes an identical operation in all the batches, regardless of size, five prototypes or five thousand units. The combination of tooling and the production processes provides incomparable speed and flexibility. This not only assists clients in reducing the development time but is also useful in short-run production of high repetitiveness.

Integrated Assembly and Finishing

The right finishing and assembly are unaccomplished without precision machining. The best CNC machine creates excellent parts, but it takes skilled assembly and expert surface finishing to complete the product. These processes determine the end quality, look, and life of the part. Effective post-machining also leads to less lead time and an efficient supply chain.

Value-Added Services That Ensure a Finished Product

The added value in the services provided by AMS Vietnam increases the value of the product once the machining has occurred. They have more than 40 surface and post-machining treatments, which are all carried out in-house. These processes include anodizing, polishing, coating, and part marking. They maintain every process and follow it closely in order to have consistent results.

Clients do not have to incur the troubles of outsourcing final processes, which can result in delays or even poor output. With the provision of all the services at a single point, they save on time spent by customers and improve satisfaction. They deal with prototypes and shipping everything, and make sure that every piece meets the highest expectations in appearance, strength, and precision.

Conclusion

Choosing the best CNC machine means looking beyond hardware—it’s about finding a supplier that understands accuracy, tooling, finishing, and full-cycle support. All things have to go hand in hand to provide high-quality parts in tandem with each other. They provide such a combination, which has advanced equipment and specialist technical teams. Their fully featured CNC machine offers what precision manufacturing requires.

With prototyping and design to the end delivery, they make every process thoroughly approached with competence and attention. They have a track record in the industry since they use integrated services, adhere to strict quality control standards, and use contemporary machining tools. Companies that want sustainable performance and precision manufacturing must consider the full-service machining offered by AMS Vietnam.

👉 Stay connected with us on Facebook for the latest updates and insights from AMS Vietnam.

FAQs

- Why should AMS Vietnam be preferred as the partner for high-precision machining?

They are equipped with modern CNC machines with having rigid quality control system. Their validated systems make each component comply with high levels of accuracy as per the world standards. They also make complete production cycles on the same roof.

- What are their strategies to maintain part accuracy?

They have more than 30 machines, where they have advanced 4-axis CNC and Swiss lathes. Different projects will be checked with CMM and Laser inspection several times. This will ensure tolerances are high all the time.

- What materials that they deal with in machining engagements?

Their machines aluminum, steel, and plastics, etc. They have flexible tooling systems to accommodate diverse materials. This assists in satisfying various design and strength needs.

- Do they have the capacity to work on prototypes as well as mass production?

Yes, they do provide full-cycle manufacturing, including prototyping to bulk orders. Rich in rapid tooling, design verification, and scale to volumes, their workflow entails these aspects. This makes production smooth at each stage.

- Do they offer post-finishing processing and surface finishing?

Well, they have more than 40 value-added services, of which anodizing is one of them. In their team, every component is completed according to the specifications of the customers. These are measures that create longevity and style.