CNC Turning Service

AMS offers high precision turning parts and service, repeatability, and efficiency, making it suitable for manufacturing.

Trust by

Precision CNC Turning Service

CNC turning is a precision machining process that uses a computer-controlled lathe to shape cylindrical parts by removing material from a rotating workpiece with a stationary cutting tool. It is ideal for creating round, symmetrical parts such as shafts, bushings, and housings. The process involves programming the CNC lathe with design specifications, fixing the workpiece, and using cutting tools to remove material according to the program. We have 3 types of precision CNC technology. Depending on the type and quantity of products required. We will choose the appropriate technology to produce for you with competitive price, fast time and stable quality.

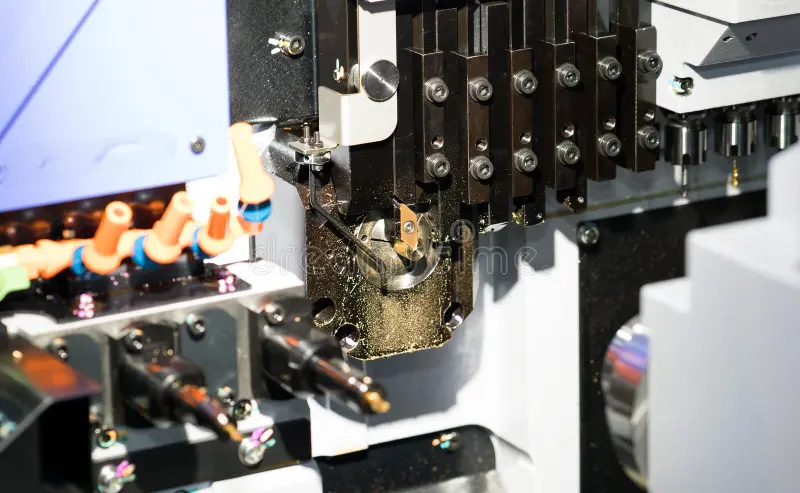

CNC Turning

CNC Turning Services Shop offers precision and consistency for complex, high-quality parts.

Automatic Lathe

Our facilities are equipped with automated lathes, capable of meeting any production requirements from our customers.

Swiss Turning

We have experts in CNC Turning Services, enabling us to meet any customer requirements.

Capabilities

Using the latest CNC machines, AMS produces highly accurate, quick turn parts in as fast as 3-5 days. We also instantly quote CNC machined parts, cutting days off of your RFQ process. AMS offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs. We are the experts in making parts that are truly custom and ready to use.

10+

Years of Industrial Experience

Measuring Machines & ISO certificates.

Using state-of-the-art Coordinate Measuring Machines (CMMs), laser scanners, and vision systems, we achieve precision measurements down to micrometers, verifying part dimensions, tolerances, and finishes.

Our CNC Turning facility is ISO 9001 certified. Each project complies with relevant regulations, such as AS9100 for aerospace components and ISO 13485 for medical devices.

Quality of service that no one can match

At AMS, we are committed to producing a high precision machined quality product to the CNC Turning Services specifications while providing excellent on time delivery performance. Our inspection expertise and experience, sophisticated inspection equipment, and ISO 9001 certification ensures a high-quality experience for our customers.

People Say The Nicest Things

Our commitment to precision, quality, and on-time delivery has earned the trust and loyalty of our clients.

Jeniffer Smith

CHEF

Pamela Duncan

DIRECTOR

I had an amazing experience with CNC Turning Services! The customer service was top-notch, and the product exceeded my expectations. I highly recommend them to anyone looking for quality products and excellent service.

Steve Tailor

CFO

Don't Know What To Start With?

Get A Solutions For CNC Turning Services

Offices

Head Office

We supply high-precision machined parts at high quality and with OEM/ODM services. We had 10 years experience to exported precision machine parts to the world as USA, EU, Australia, Canada,…